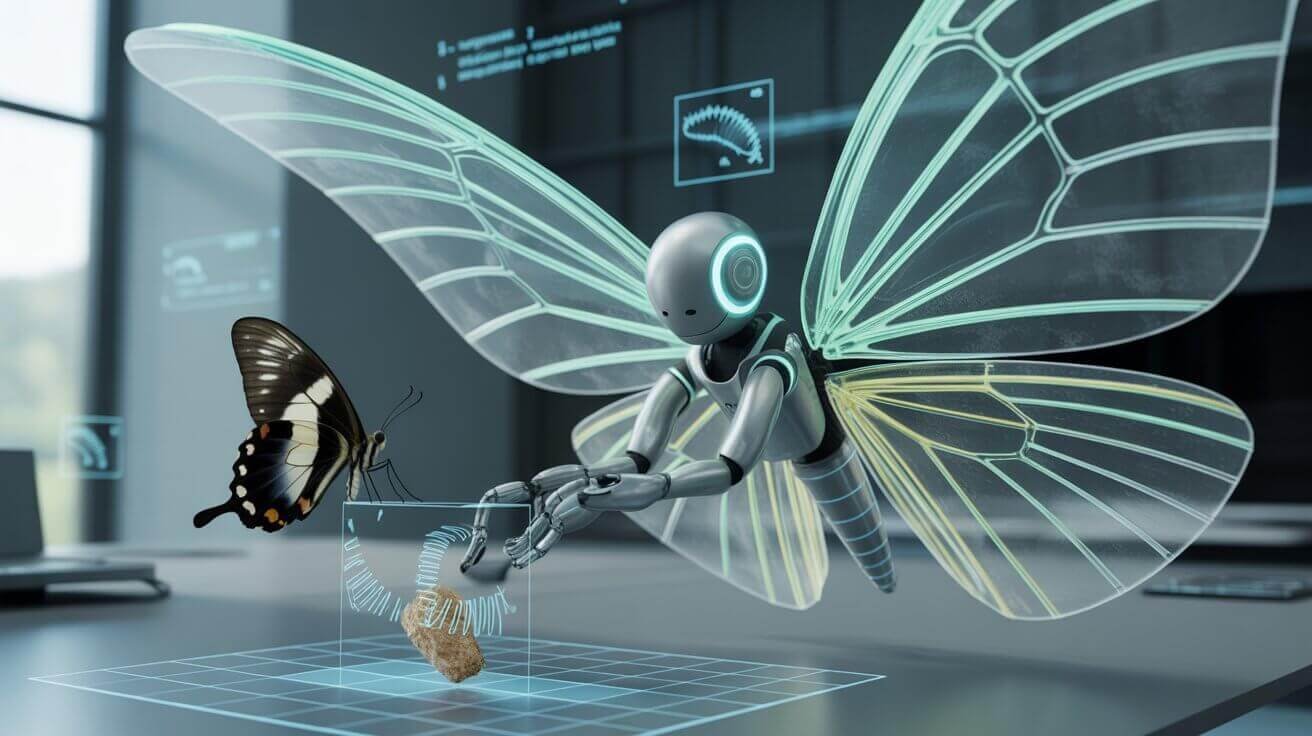

Watch a butterfly land on a flower, and you’re witnessing millions of years of engineering perfection. Meanwhile, the wings are bending, twisting, and adapting to air currents with a precision that makes our best robots look clunky. That’s exactly why biomimetic soft robotics has become one of the most exciting frontiers in technology.

Scientists are discovering that insects hold the blueprints for creating robots that can move through our world with unprecedented flexibility and efficiency. Moreover, biomimetic soft robotics is transforming how we think about automation, from delicate surgical procedures to disaster rescue operations where traditional rigid robots simply can’t function.

But here’s what makes this field truly fascinating: we’re not just copying nature anymore. We’re learning to understand it at a molecular level and then improving upon it.

What Makes Insect-Inspired Design So Revolutionary

Traditional robots are built like tanks – sturdy, predictable, but limited in their interactions with complex environments. However, insects show us a completely different approach. Furthermore, their secret lies in controlled flexibility rather than rigid precision.

Take a look at how a bee navigates through dense vegetation. Its wings don’t just flap up and down; they twist, bend, and adjust their angle thousands of times per second. Additionally, researchers have discovered that butterfly wings contain strain receptors that detect wind direction with 99% accuracy, providing real-time feedback for flight adjustments.

This biological sophistication has inspired biomimetic soft robotics to move beyond simple mimicry. Consequently, engineers are now creating robots with shape-memory alloys that contract up to 50% of their original length, similar to how worm muscles work. These materials respond to heat, electricity, or chemical signals, enabling robot bodies to literally reshape themselves for different tasks.

The Secret of Soft Actuation

What’s particularly compelling about insect-inspired actuation is how efficiently it converts energy into motion. For instance, researchers have developed flapping mechanisms using shape-memory alloys that create sinusoidal undulations with 0.17 Hz frequency, comparable to real worms.

Furthermore, these bio-inspired actuators overcome the limitations of traditional electric motors, which are often too bulky for small robots. Instead, biomimetic soft robotics uses materials that can store and release energy like biological muscles, dramatically improving efficiency.

Real-World Applications That Are Already Here

The applications for biomimetic soft robotics aren’t just theoretical – they’re solving real problems today. Subsequently, the market is responding with impressive growth projections.

The global soft robotics market was valued at $2.58 billion in 2024 and is expected to reach $38.17 billion by 2034, growing at a CAGR of 34.9%. Similarly, the broader biomimetics market is projected to grow from $22.3 billion to $48.5 billion by 2033.

Medical Breakthroughs

In healthcare, biomimetic soft robotics is enabling minimally invasive surgery with unprecedented precision. Soft grippers can handle delicate tissues without causing damage, while flexible endoscopic tools navigate the human body’s curves naturally.

Moreover, rehabilitation robotics is being transformed by insect-inspired design principles. Soft exoskeletons that mimic muscle movement are helping patients with neurological conditions regain mobility. These devices are lighter and more comfortable than traditional rigid exoskeletons because they work with the body’s natural movement patterns.

Industrial Innovation

Manufacturing is another area where biomimetic soft robotics excels. Furthermore, soft grippers inspired by insect feet can handle irregular shapes, fragile electronics, and food products that would be damaged by traditional robotic hands. Companies report that soft grippers account for 37.4% of the soft robotics market, driven by their versatility in automated assembly lines.

Disaster Response and Exploration

Perhaps most impressively, biomimetic soft robotics is creating new possibilities for search and rescue operations. Robots that can squeeze through debris, navigate unstable terrain, and operate in environments too dangerous for humans are becoming reality.

Additionally, space exploration benefits from insect-inspired design. NASA has developed gecko grippers using millions of microfibers that create adhesive forces similar to gecko feet, enabling robots to cling to surfaces in zero gravity.

The Technology Behind the Magic

Understanding how biomimetic soft robotics actually works reveals why it’s so effective. Essentially, these systems combine multiple cutting-edge technologies into cohesive platforms.

Material Science Breakthroughs

The foundation of biomimetic soft robotics lies in smart materials that can change their properties on command. Shape-memory alloys remember their original shape and return to it when heated. Dielectric elastomers expand and contract when electrical fields are applied. Liquid crystal elastomers respond to light, heat, or chemical signals.

Furthermore, researchers are developing materials that combine multiple responsive properties. For example, some soft robots can lift heavy objects, heal themselves, and climb significant heights while maintaining human-like flexibility.

Sensory Integration

Just as insects use multiple sensory inputs to navigate their environment, biomimetic soft robotics incorporates various sensing technologies. Strain gauges embedded in flexible wings can detect airflow patterns. Pressure sensors in soft grippers provide tactile feedback. Vision systems guide overall movement.

Moreover, artificial intelligence processes this sensory data in real-time, enabling adaptive responses to changing conditions. Machine learning algorithms can classify wind patterns with 99% accuracy using wing deformation data, revolutionizing flight control strategies.

Control Systems

Controlling biomimetic soft robotics requires fundamentally different approaches than traditional robotics. Instead of precise joint angles and rigid trajectories, these systems use distributed control strategies that coordinate multiple flexible elements.

Additionally, many soft robots employ what’s called “morphological computation” – letting the physical structure of the robot contribute to information processing. This reduces the computational burden while enabling more natural, adaptive movements.

Challenges We’re Still Solving

Despite remarkable progress, biomimetic soft robotics faces significant technical and practical challenges. However, addressing these obstacles is driving innovation across multiple disciplines.

Power and Speed Limitations

Current soft actuators often operate slower than their biological counterparts. For instance, SMA-actuated robots typically achieve speeds between 0.25 mm/s and 9 mm/s, considerably slower than natural insects.

Furthermore, power density remains a challenge for untethered operation. Soft robots require energy not just for movement but also for heating shape-memory alloys or generating electrical fields for actuation.

Durability and Reliability

Biological systems self-repair and adapt to damage, but current biomimetic soft robotics struggles with long-term durability. Flexible materials experience fatigue, and complex sensing systems can fail in harsh environments.

Nevertheless, researchers are making progress with self-healing polymers and redundant sensing networks that maintain functionality even when individual components fail.

Manufacturing Complexity

Creating biomimetic soft robotics with the precision and integration of biological systems requires advanced manufacturing techniques. 3D printing and 4D printing technologies are enabling more sophisticated designs, but scaling production remains challenging.

Additionally, the interdisciplinary nature of biomimetic soft robotics requires collaboration between biologists, materials scientists, engineers, and computer scientists – a coordination challenge in itself.

What’s Coming Next: The Future of Bio-Inspired Machines

The trajectory of biomimetic soft robotics points toward increasingly sophisticated systems that blur the line between biological and artificial. Consequently, several emerging trends are shaping the field’s future.

Hybrid Bio-Artificial Systems

Researchers are developing systems that combine living tissue with synthetic materials. These bio-hybrid robots could have the self-repair capabilities of biological systems while maintaining the precision and programmability of engineered devices.

Moreover, genetic modifications are being used to analyze insect sensory mechanisms, potentially leading to robots with biological sensory organs.

Swarm Intelligence

Individual insects are impressive, but insect swarms demonstrate emergent intelligence that surpasses any individual. Similarly, biomimetic soft robotics is moving toward coordinated swarms of simple robots that collectively accomplish complex tasks.

Furthermore, distributed sensing and communication networks enable swarm robots to share information and coordinate responses to environmental changes in real-time.

Adaptive Learning

Future biomimetic soft robotics will incorporate advanced AI that enables continuous learning and adaptation. These systems will modify their behavior based on experience, developing new movement strategies and optimizing performance for specific environments.

Additionally, neuromorphic computing architectures inspired by insect nervous systems could enable more efficient onboard processing for real-time decision making.

Scalability Across Sizes

Current research spans from microscale robots for medical applications to larger systems for industrial use. However, the principles of biomimetic soft robotics remain consistent across scales, suggesting broad applicability.

Moreover, modular designs inspired by insect body segments could enable robots to reconfigure themselves for different tasks or environments.

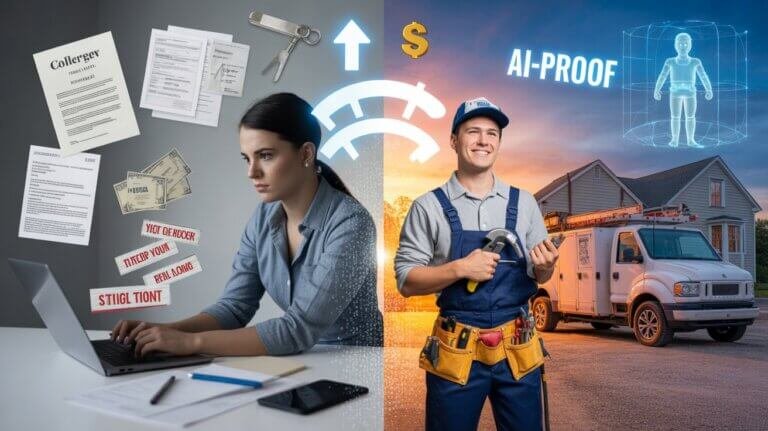

Why This Matters for Everyone

The implications of biomimetic soft robotics extend far beyond academic research or niche applications. Essentially, this technology is reshaping our relationship with machines and opening possibilities we’re only beginning to understand.

In healthcare, these systems promise less invasive procedures, more effective rehabilitation, and assistive devices that seamlessly integrate with human movement. Furthermore, industrial applications could make manufacturing more flexible and adaptive to changing demands.

Environmental monitoring and conservation efforts benefit from robots that can operate in natural environments without disrupting ecosystems. Additionally, disaster response capabilities continue expanding as soft robots become more capable of operating in unstable, dangerous conditions.

Perhaps most importantly, biomimetic soft robotics represents a shift toward technology that works with natural systems rather than against them. This approach could lead to more sustainable, efficient, and harmonious integration of artificial systems into our world.

The insects buzzing around your garden aren’t just fascinating creatures – they’re unwitting teachers, showing us how to build the next generation of robots. And those lessons are transforming not just technology, but our entire approach to solving complex problems through nature-inspired innovation.